James Bond movies and television shows have made “Bulletproof Glass” a household name. It has become a mysterious enigma, so to speak. We will try and dispel the mystery and misinformation about bulletproof glass.

James Bond movies and television shows have made “Bulletproof Glass” a household name. It has become a mysterious enigma, so to speak. We will try and dispel the mystery and misinformation about bulletproof glass.

In the real world, “bullet proof” does not exist. When speaking in terms of protection from hand guns and rifles the proper term is bullet resistant, as nothing is truly bulletproof. If given enough time and effort, any bullet resistant product can be defeated.

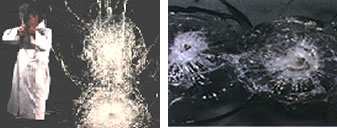

Bullet resistant glass is not at all like it has been portrayed. In movies and TV, bullet resistant glass is portrayed as being no thicker or different from “normal” glass. Bullet resistant glass is often assumed to be “bulletproof,” and it is assumed that it just stops bullets with no regards what is being shot at the glass from a small handgun to rockets. On TV, the bullets just bounce off the glass and away you go! The photo below shows the impact of a bullet into real bullet resistant glass. (Note that the bullets are embedded into the glass)

Bullet resistant glass is manufactured in different protection levels: from level 2, stopping handguns such as .9mm & .357 Magnums at .825″ thick, to our Level 8- Armor Piercing Protection from a .30-06 Rifle at 2.27″ thick. As the level of protection increases, so does the weight, thickness and price.

Bulldog Direct’s Bullet Resistant Glass Is Available In Several Versions:

Bulldog Direct’s Bullet Resistant Glass Is Available In Several Versions:U.L. Listed | All Glass | Glass – Clad Polycarbonate

In – Low -Spall and No -Spall Configurations:

Low Spall: (Glass on the protected side)

No-Spall : (Polycarbonate on the protected side)

What are your three types of bullet resistant glass?

1: U.L. Listed Flat Sheet Bullet Resistant Glass, tested by H.P. White Laboratories Inc., offers you an affordable bullet resistant glass system when Underwriters Laboratories [U.L.] listing and testing is required. This is the most costly of our three Bullet Resistant Glass Systems.

2: Our All Glass Flat Sheet Bullet Resistant Glass, tested by H.P. White Laboratories Inc., is a very economical Bullet Resistant Glass System. Our All-Glass is the least exspensive of our three systems. It is also the thickest and heaviest of our three Bullet Resistant Glass Systems.

3: Our Glass-Clad Polycarbonate Flat Sheet Bullet Resistant Glass Tested By: H.P. White Laboratories Inc. is a very economical Bullet Resistant Glass System. It is also the Lightest and Thinnest of all of our 3 Bullet Resistant Glass Systems.This is an extremely durable and light-weight transparent armor , Combining the hard surface of glass with the resilient toughness of poloycarbonate, Our Glass Clad systems are specially designed to defeat threats from high-powered firearms with low-spall or no-spall performance. Mid price level of our 3 Glass Systems.

Our Glass-Clad Polycarbonate:

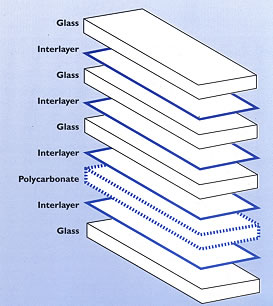

Bullet Resistant Glass in a glass-clad polycarbonate make-up is a multi-ply composite laminate combing polycarbonate and glass using special polyurethane high adhesion bonding interlayers which allow for the expansion/contraction differential of both materials. This special interlayer and the manufacturing process are key elements in controlling the 10:1 thermal expansion ratio. This design allows us significant latitude to almost any ballistic threat from .9mm handguns to .30-06 armor piercing rounds. Combining the the obvious advantages of glass and polycarbonate provides three primary benefits over ALL-Glass composites. #1= Thickness and weight savings up to 60% over conventional ALL-Glass systems. #2= Multiple impact protection and high ballistic protection from rifles. #3= The high structural integrity of polycarbonate with the abrasion, chemical, flame resistance of glass.

Polycarbonate is plastic material thirty times stronger than acrylic, which is seventeen times stronger than an equal thickness of single strength glass. Polycarbonate, therefore, is an excellent impact barrier and is used as the core material of our bullet resistant composite. Polycarbonate is susceptible to abrasion, scratching, chemical attack, heat and flame. Polycarbonate alone is not an effective ballistics barrier above handgun protection. Our solution is a combination of these materials to take advantage of their benefits while eliminating their individual shortcomings.

Bulldog Direct’s Bullet Resistant Glass provides ballistic protection that is designed to defeat National Institute of justice [N.I.J.] and Underwriters Laboratories [U.L.] threat levels.

What Level of Protection Do I Need?

Most ballistic attacks in the USA occur using handguns, the most popular being a .9mm or .357 Magnum handgun. In other parts of the world, the weapons of choice is the AK-47 assault rifle. In South America, the ballistic threat could be a .9mm handgun to an M-16 assault rifle. Bad guys tend to shoot at what they can see. Rarely are weapons shot at walls, car doors, etc., other than your occasional drive-by shooting.

Threat assessment is the first step in deciding which protection level you need.

1: Very High Threat Level: You have been shot, or shot at. You or your business has been robbed. Any government buildings, military installations, guard booths, nuclear power plants, etc. Your Bullet Resistant Glass needs are very serious and you need to purchase immediately.

2: High Threat Level: You have been threatened, stalked, or own a liquor, jewelry or check cashing store. You may live in an area subject to gang violence or drive-by shootings. Your Bullet Resistant Glass needs are serious and real. You need to evaluate your threat and purchase Bullet Resistant Glass within 30-90 days.

3: Medium-Low Threat Level: You are building a “Safe Room”, you have never been shot, or shot at. Your needs are proactive. You are evaluating your threat and purchasing bullet resistant glass may be a consideration.

Can anyone purchase Bullet Resistant Glass?

Purchasing and installing Bullet Resistant Glass Systems in the USA is perfectly legal. No police or government permit is required. We do suggest contacting your local building/fire inspector with regards to building codes, inspections or permits needed.

Can Bullet Resistant Glass made to any size?

Bullet Resistant Glass can be custom manufactured to most sizes. However, it is important to keep in mind when considering the purchase of Bullet Resistant Glass that with size, comes weight. In most cases our Bullet Resistant Glass is used to replace glass from an existing window. Most of the units we sell are under 4’x8′. Large Bullet Resistant Glass units over this size are very heavy, thus shipping, boxing and safe installation are more difficult. Please feel free to call us with any questions or special requests you may have at 513-281-6700.

Question: Is Bullet Resistant Glass Expensive?

Answer: Most individuals have never been in the market for Bullet Resistant Glass and have nothing to base a price quotation on, other than what they feel the price should be. An informed consumer is always in a better position to make a decision with the proper knowledge and information. Pricing for Bullet Resistant Flat Glass can start from around $25.00 per sq.ft. to over $100.00 per sq.ft. (Depending on sheet size and level of protection needed.)

How our Glass-Clad Polycarbonate Bullet Resistant Glass is Manufactured

Layout and Cutting: The first step in the manufacturing process is cutting all of the needed window units from flat sheet glass stock, along with the sheets of polycarbonate and polyurethane bonding interlayers. The first layer of of glass is cut to the exact size of measurements. The next layer is the first of several of polyurethane bonding interlayers. The next set of glass is cut as described above. The final “lay-up” can be from 2-5 units of glass and 1-2 layers of polycarbonate. The protected side of your Bullet Resistant Glass can be manufactured for you in two ways: Low Spall: Glass on the protected side / No-Spall : Polycarbonate on the protected side.

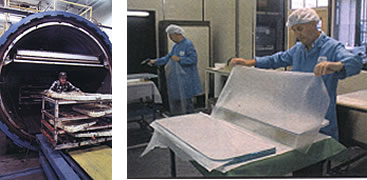

Clean Room Assembly: All the individual units are then completely cleaned. We now take the cleaned “lay-up” to our cleanroom for final assembly. There, all the glass and the layers of polyurethane bonding interlayers are assembled in the proper configuration. Then, we thoroughly inspect the final assembly for proper size, and for defects in the manufacturing process. Our General Manager, Shop Foreman, and Production Manager must all check off on the final assembly before it is sent to the autoclave for final bonding of the unit.

Vacuum Bag Assembly: After passing our very stringent inspection, the full “lay-up” is then inserted into a vacuum bag and sealed. We then pull a vacuum on the bag, removing all of the air.

Autoclaving: The final step in manufacture is loading the vacuum bagged assembly in to one of our two large autoclaves. (These are just a slightly larger version of what your local dentist uses to sterilize their instruments.) The heat and pressure of the autoclave bonds all of layers of polyurethane, glass, and bonding interlayers together. The autoclave cycle takes 12 hours to bond the vacuum bagged assembly into the finished product. It also takes about 8 hours for proper cooldown time.

Final Inspection & Boxing: After the finished Bullet Resistant Glass has been removed from the autoclave, it is rechecked against the drawings and specifications. Again our General Manager, Shop Foreman, and Production Manager must all check off on the final assembly before it is boxed for shipment to you.

Tested By: H.P. White Laboratories Inc.